HOT STRIP MILL FOR SALE

ITEM CODE

HILOR150HSM

HOT STRIP MILL FOR SALE

800,000 T/Y

June 2024

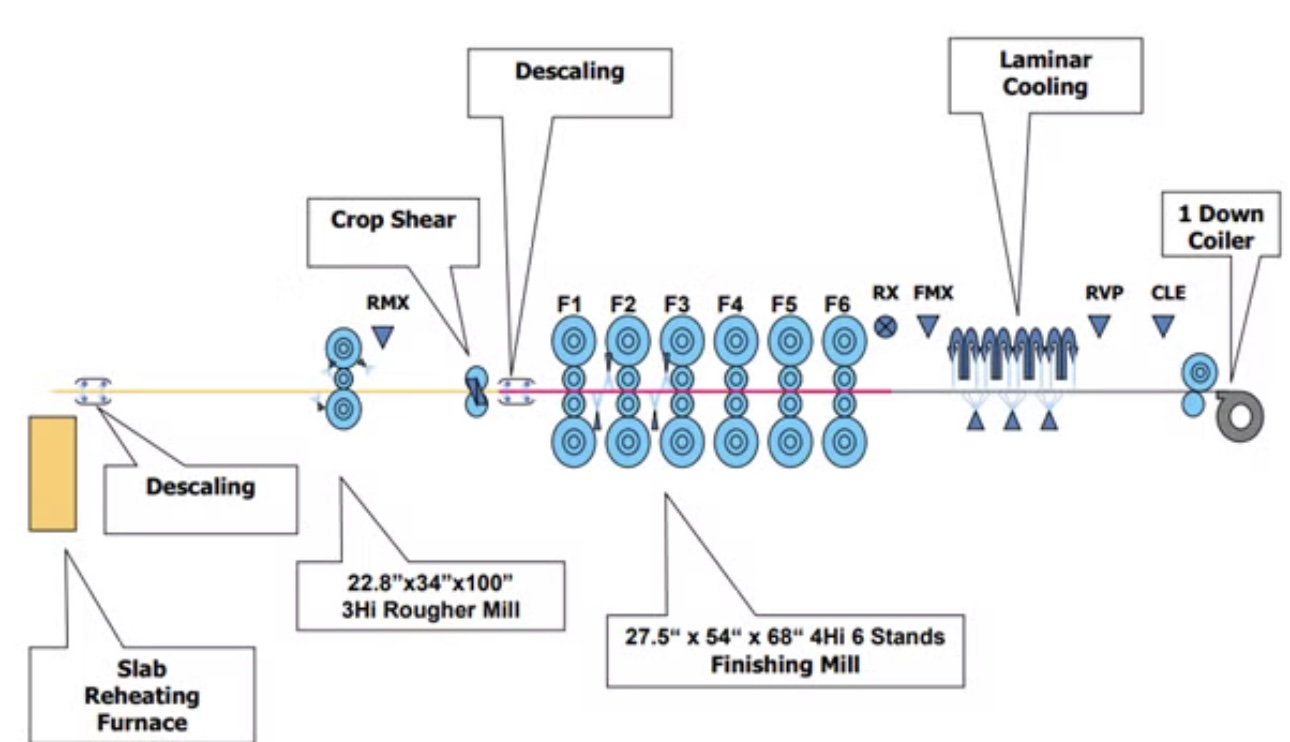

THE HOT STRIP MILL CONSISTS OF

Single Slab Reheat Furnace

• Type: Walking Beam

• Manufacturer: Davy

• Capacity: 150 t/h

• Inside Refractory Width: 8,35 m

• Effective Length: 32,6 m

• Slab Thickness: 160 mm

• Slab Maximum Length: 7,5 m

• Primary Fuel: mixed BFG and COG

• Alternate Fuel: N°6 Fuel Oil

• Commissioned in 1995

Water Descalers

• Primary descaler at slab reheat furnace run out table

• Front and back 3 Hi Rougher Mill descalers.

• Finishing Mill descaler at run-in table.

Water Descaling Pumps

• Manufacturer: Union Pump Company

• N° of Pumps: Two (one operating, one stand by.)

• Power: 5.000 HP (3.730 kW)

• Pump Speed: 4.500 rpm

• Discharge Pressure: 127 barg (1.840 psig)

Rougher Mill

• Type: 3 Hi, one stand 22" x 34" x 100" Reversing Mill

• Manufactured by Blaw-Knox in 1923.

• Main Motor : Synchronous type

• Main Motor Power: 6000 HP

• Motor Speed: 250 rpm

• Maximum Rolling Force: 700 t

• Maximum Edger Force: 100 t

• Edger Motor Power: 300 HP (224 kW)

• Transfer Bar Speed: 2,9 m/s

Crop Shear

• Drum Type Rotary Crop Shear

• Manufacturer: United

• Maximum Transfer Bar Section: 32 x 1575 mm at 940 °C, 0,4%C Carbon Steel

• Maximum Transfer Bar Speed: 2.5 m/s

Finishing Mill

• Type: 4 Hi 6 Stands

• Mechanical Manufacturer: United

• Electrical Manufacturer: General Electric

• Roll Barrel: 1.727 mm (68”)

• Work Rolls Diameter: 699 mm (27,5”)

• Back-Up Roll Diameter: 1.380 mm (54”)

• Maximum Rolling Force Stands 1 to 4: 2.400 t

• Maximum Rolling Force Stand 5: 2.000 t

• Maximum Rolling Force Stand 6: 1.600 t

• Electromechanical Screw down Stands 1 to 4

• Electromechanical Screw down & hydraulic capsules in Stands 5 & 6.

• 40 t per chock work roll bending per stand.

• Main Drives Stands 1 and 2: 6.000 HP (4.476 kW)

• Main Drives Stands 3 to 5: 5.000 HP (3.730 kW)

• Main Drive Stan 6: 4.000 HP (2.984 kW)

• All main drives are DC with thyristor speed control.

• Maximum Finishing Speed: 830 m/min

• Two X-Ray Gages

• Commissioned in 1970 (Stands 3 to 6) and revamped in 1995 (Adding Stands 1 & 2)

Laminar Cooling

• Seven Cooling Sections

• Three Control Zones

• Total Water Flow: 5.270 m³/h

• Upper Face Cooling: 4.100 m³/h

• Bottom Face Cooling: 1.170 m³/h

• Water Pressure: 2,5 barg

Single Downcoiler

• Two Wrapper Rolls pneumatically activated.

• Maximum Coil Width: 1.575 mm (62”)

• Maximum Coil Weight: 20 t

• Maximum Coil Diameter: 1.727 mm (68”)

• Mandrel Diameter: 724 mm (28.5“)

• Strip Thickness: 1,8 to 12,7 mm

COMPLETE MELT SHOP

THE BEST CHIOCE IN SAUDI ARABIA

EAF

COMPLETE MELT SHOP

150,000 T/Y

JUNE 2024

150.000 TPY EAF-MELT-SHOP

with

CONTINUOUS-BILLET- CASTER 130 mm

The Equipment was purchased over a 10-year period, starting in 2004. But recently management of the owners Siderurgica Sao Joaquim, Brazil decided to purchase the billets and not get involved in steelmaking. The Buyer needs to invest in completing the Installation. Danieli prepared a report on you what further investments are needed.

30 Ton EAF (Electric Arc Furnace) “CONCAST”

Shell: Spout type; Diam. 4.0 M; Shell height 1.3

Int. Panels diam. 3.8 M; Hot heat 5 Ton; Bucket volume 23.0 M³; El. Pitch diam. 900 mm; Electrode diam. 16”

Tap-to Tap Time 90 min.; Power on 73 min.

Transformer 17/20 MV.

Capacity Based on 7.200 hrs.= 173.000 Ton

Hydraulic Unit “REXROTH”

CONTINUOUS BILLET CASTER Mfg. “HAS Engenharia”

3-Strand; Radius 8 Meter

Billet size from 100 x 100 to 150 x 150 mm x 6 Meter

Withdrawal Unit; Oxygen Billet Cutting;

Coolant Bed (turn-over) 12 M.

AUXILIARY EQUIPMENT

• 75 Ton Overhead Crane “BIVIGIA”; span 18 Meter

• 40/20 Ton Overhead Crane “BIVIGIA”; span 18 Meter

• BAGHOUSE/DEDUSTING PLANT Mfg. “PRODUMAR TECNOLOGIA MARELLI”;

• 3 x Scrap Buckets

• 2 x Transfer Cars

• 3 x Ladles

• 3 x Tundishes

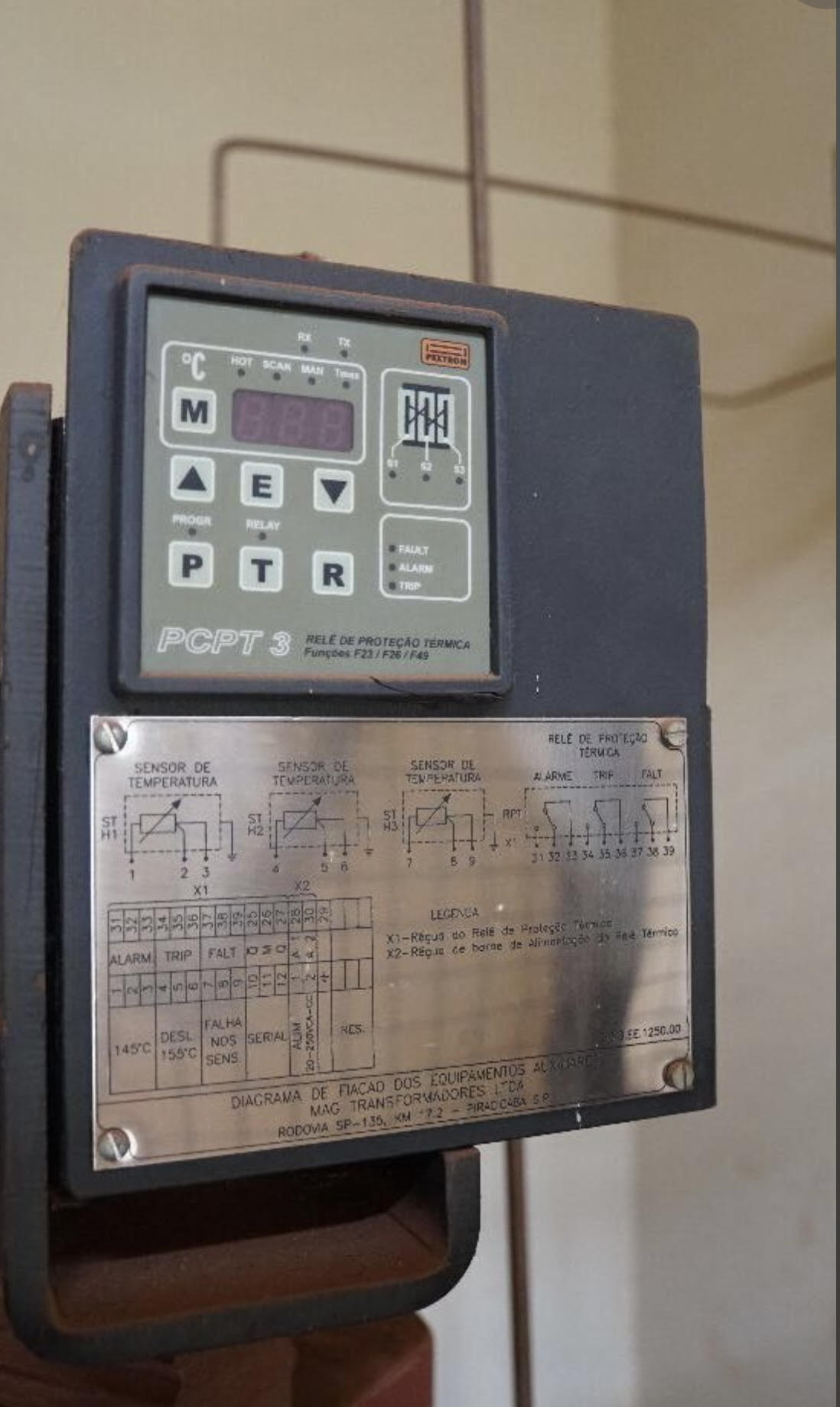

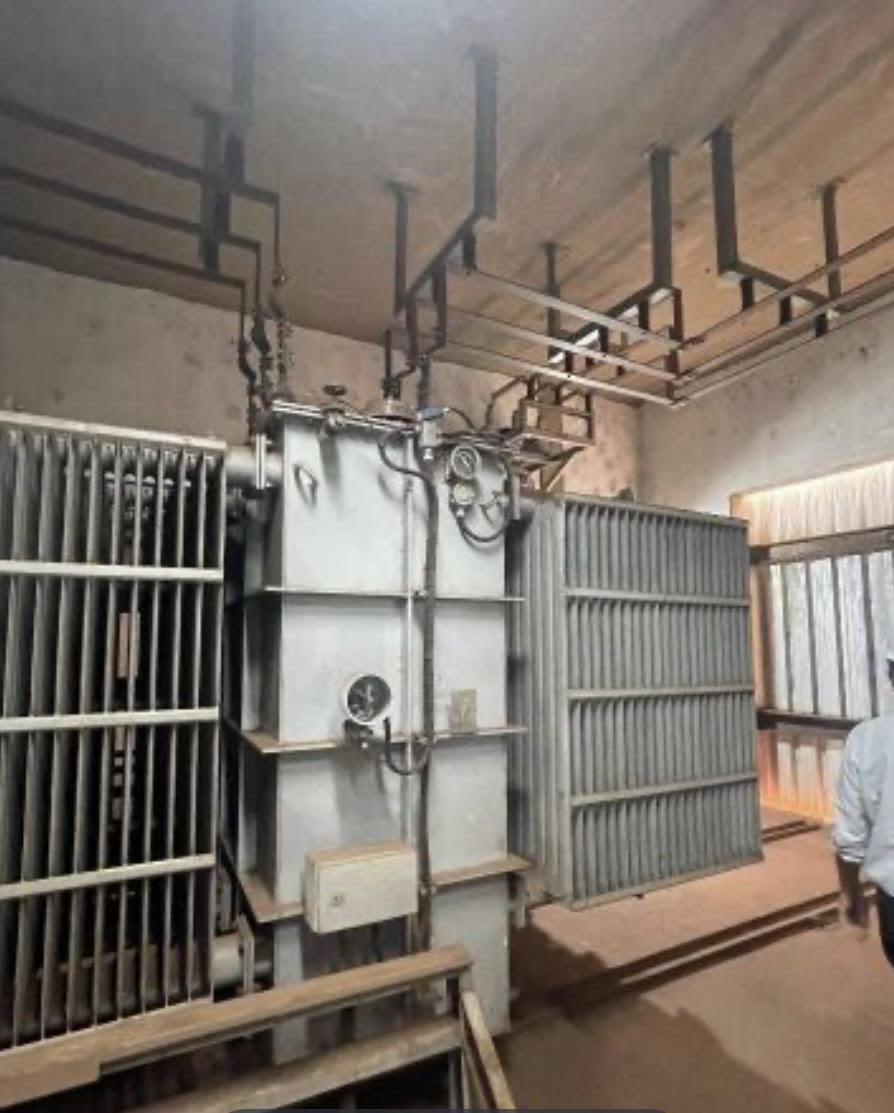

TRANSFORMERS:

THREE-PHASE DRY TRANSFORMER MAG MOD. T3 2000 CAP. 2000KVA 13800440V

DRY THREE-PHASE TRANSFORMER CAP. 50KVA 440380-220V

IMAGE CATALOG- HYDRAULIC SYSTEM AND THREE-PHASE DRY TRANSFORMERS

SLITTING LINE OF STELL ROLLED COILS

1500 X (0.2 - 3) MM

.

A slitting line ex new with a warranty of one year composed of

120m / minute Stainless Steel Slitting Line - Completely

re-manufactured with brand new power cabinets, control

panels, PLC, HMI

• Brand new safety fencing

• New edge guide

Line direction: Left to Right

Line layout dwg. in the Attach., at the bottom of the page

• min. coil width: 160 mm

• material thickness: 0.2 mm to 3 mm

• max. 7 cuts at 3.0 mm carbon steel (R=450);

max. 2 cuts at 3.0 mm stainless steel <

• max. cutting section: 110kg/mm2

Slitter shaft dia.: 160mm

Slitter knife dia.: 300mm

25 ton Decoiler &Car

12 ton Recoiler

6m loop pit

entry Coil ID: 508mm; 610mm using spacers

exit Coil ID: 508mm

entry max. Coil OD: 1500mm

exit max. Coil OD: 1500mm

Main Line Parts :

( now repainted in blue and yellow )

• L-shaped Coil Loading Car

• Mobile Base Decoiler

• Coil Threading Table

• Pinch Rolls

• Centering/Entry-Unit to Slitter

• Slitter with hydraulically-opening stand

• Scrap Baller

• Loop Pit Go-Beyond Gripper

• Roll Cradle with Separator Holders

• Felt Tension Pad

• Crop Shear

• Fixed Deflector Roll & Recoiler Entry Table

• Fixed Base Recoiler with coil ejection plate

• Coil Off-Loading Car with sectional strip hold-

down

• 2-Arm Turnstile

• Entry Quadrant Rolls to loop pit

• almost total weight 52 TON

3

• Exit Quadrant Rolls from loop pit

• Hydraulic Power Pack

Installed Power

Decoiler 25 kW DC 460-1600rpm

Slitter 85 kW DC 1700rpm

Recoiler 100 kW DC 529-1600rpm

Scrap Baller 14kW AC 1450rpm

Hydr. Power Pack 14kW AC 1450rpm

THE ITALIAN MADE

A GOOD CHANCE OF YOUNG INVESTORS IN SHEET METAL WORKING

C A L L N O W

©Copyright. Tutti i diritti riservati a orsteel

Abbiamo bisogno del vostro consenso per caricare le traduzioni

Per tradurre i contenuti del sito web utilizziamo un servizio di terze parti che potrebbe raccogliere dati sulla vostra attività. Si prega di rivedere i dettagli nell'informativa sulla privacy e accettare il servizio per vedere le traduzioni.